Why Every EV Lab Needs a Battery Cycler with Data Analytics

As the electric vehicle (EV) revolution gains traction

across the globe, educational institutions and research centers are racing to

equip themselves with the tools and technologies needed to prepare the next

generation of engineers. At the heart of any meaningful EV research and

training lab lies a critical component that often gets overlooked—the Battery

Cycler with Data Analytics (BCDA).

Batteries account for nearly 50% of the total cost of an EV.

Understanding how they behave under real-world conditions is crucial not just

for efficiency and safety, but also for longevity and cost optimization. That

is why every EV lab—whether focused on skill development or advanced

R&D—must have a Battery Cycler integrated with powerful analytics

capabilities.

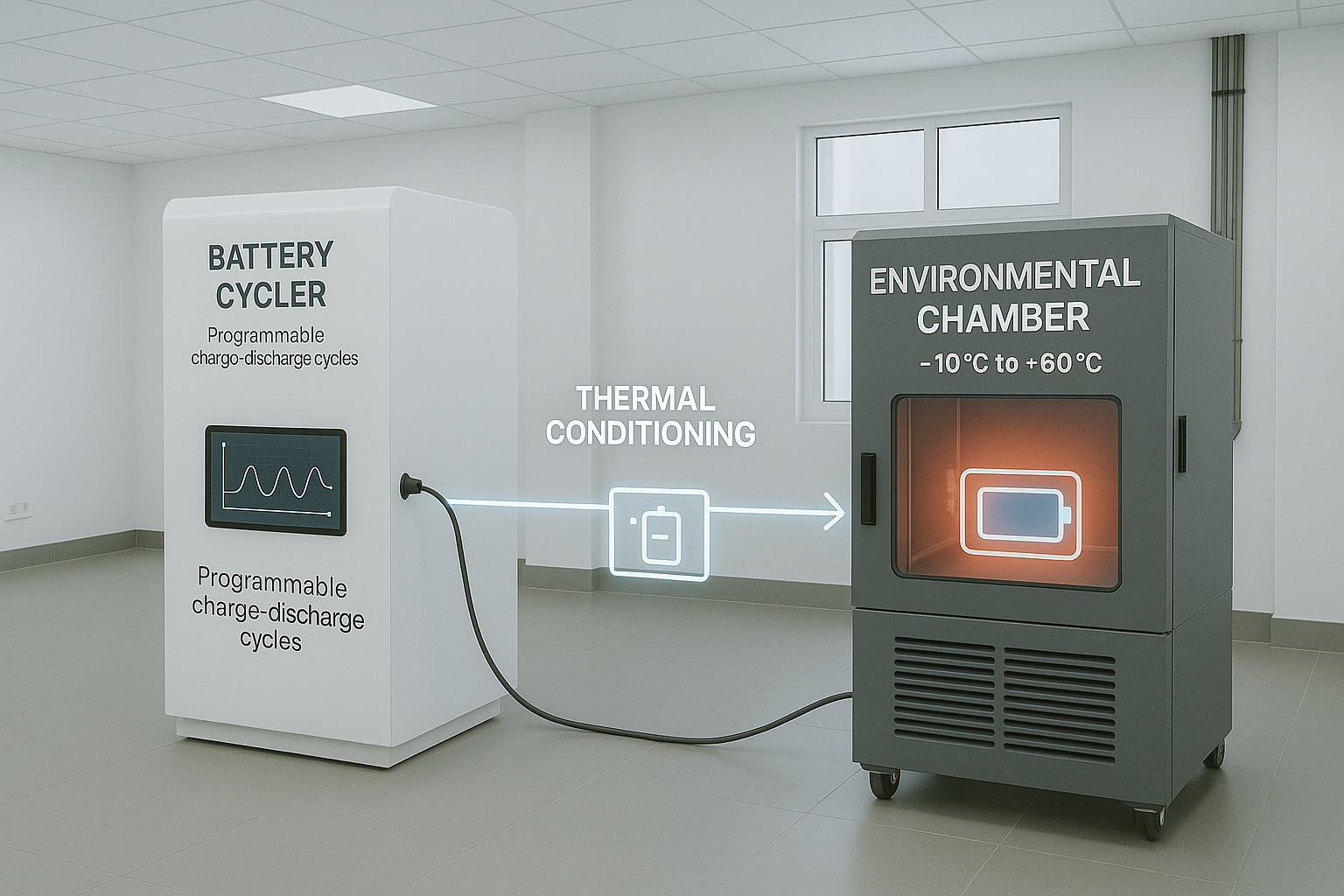

What Is a Battery Cycler with Data Analytics?

A Battery Cycler with Data Analytics is a system that

performs continuous charging and discharging of batteries under

controlled conditions, while also collecting and analyzing performance data.

Ecosense’s BCDA goes a step further by integrating an environmental chamber,

smart sensors, and a software-controlled platform that allows

students and researchers to:

- Run

customized test cases (CC, CV, CP charging)

- Monitor

voltage, current, and temperature in real-time

- Analyze

battery behavior at different C-rate

- Study

performance in extreme temperature and humidity conditions

- Evaluate

state of health (SoH) over charge-discharge cycles

- Modify

and test their own control algorithms

This transforms the EV lab from a static learning space into

a dynamic battery research environment.

Why Is It Essential in Modern EV Labs?

EVs rely heavily on battery performance, and poor battery

selection or mismanagement can lead to range anxiety, premature failure,

or inefficient energy usage. BCDA fills this educational gap by

offering:

1. Wholesome Learning and Research Opportunity

Ecosense’s BCDA is not just a tool—it’s a platform for

foundational understanding and advanced experimentation. It enables

students to not only test batteries, but to design and validate algorithms

for battery control, safety cut-offs, and efficiency optimization.

2. Integrated Learning Ecosystem

The BCDA includes a battery pack, cycler system,

and environmental chamber, all controlled via FPGA and software. This

plug-and-play model is self-contained, meaning institutions don’t need to

invest in multiple disjointed setups to run battery experiments.

3. Real EV Components for Real Results

Unlike training kits that rely on scaled-down or dummy

components, the BCDA uses actual EV-grade hardware—including a 48V, 24Ah

LiFePO₄ battery, BMS, and industrial-grade chamber—ensuring realistic outcomes

and industrial relevance.

4. Customizable and Open-Source Software

The system is built on an open software framework,

allowing faculty and students to modify control algorithms, create new

test cases, and tailor experiments to their academic or research goals.

Key Experiments You Can Run with BCDA

Here is a snapshot of the kinds of practical and

research-grade tests enabled by the Ecosense BCDA platform:

- Charging

and discharging analysis under CC, CV, and CP modes

- C-rate

testing to understand stress behaviors

- Battery

aging studies through hundreds of controlled cycles

- Fuel

economy comparisons between new and aged batteries

- Thermal

stress testing in environments ranging from -10°C to +60°C

- State

of Health (SoH) evaluation to track degradation

- Temperature

cut-off detection for BMS optimization

- Charge

profile comparisons (e.g., 0–100%, 30–100%, 50–100%)

- Calculation

of specific energy, power, life span, and cost-efficiency

These experiments are invaluable for both undergraduate labs

and PhD-level research.

The Role of Analytics in Battery Testing

What sets BCDA apart is its powerful data visualization

and control platform. The system does not just record numbers—it provides

insights. Data captured during tests is displayed as:

- Voltage-current-temperature

curves

- Charge/discharge

efficiency graphs

- Real-time

alerts for safety thresholds

- State-of-health

tracking over time

- Exportable

datasets for academic reports or publications

All this is made possible through a dedicated application

software and FPGA-based controller, giving users a clean, intuitive

interface to run tests and analyze results.

Designed for Classroom and Research Environments

Ecosense’s BCDA system is modular and scalable,

making it equally suitable for:

- Engineering

colleges and polytechnics teaching EV fundamentals

- Universities

and IITs conducting advanced battery research

- Skill

development centers offering technician training

- Incubation

hubs and startups needing rapid battery testing

With compact design, full software control, and integrated

safety features, the BCDA can be installed in regular classroom settings—no

specialized infrastructure required.

What Students and Researchers Gain

With access to a battery cycler like BCDA, learners gain:

- Hands-on

skills in battery testing, BMS design, and diagnostics

- Real-world

data analysis experience applicable to industry roles

- A

platform for innovative research, capstone projects, and

publications

- Confidence

to work with high-voltage systems and embedded controls

- Exposure

to cutting-edge tools used by leading EV OEMs

In short, BCDA does not just prepare students for jobs—it

prepares them for the next wave of EV innovation.

A Smart Investment in Battery Intelligence

In today’s EV labs, having motors, controllers, and drive

cycle simulators is important—but having a Battery Cycler with Data

Analytics is essential. It unlocks deep learning, sharpens critical

thinking, and empowers the kind of experimentation that leads to breakthroughs

in battery technology.

At Ecosense, we design BCDA not just as a piece of

lab equipment, but as an educational platform—one that evolves with your

curriculum, research needs, and technological ambitions. If your institution is

building or upgrading its EV Lab, start with the battery, and test it with

intelligence.

Ready to bring advanced battery testing to your EV Lab?

Let us power the future together.