Anna University is one of the most sought-after universities in South India. Renowned for nurturing professionals equipped with advanced technical expertise, professional acumen, and strong ethical values. It aims to sustain its position as a preferred collaborator for industry and community, fostering their economic and social advancement through exceptional teaching, research, and consultancy services. Institute of Energy Studies under Department of Mechanical Engineering, Anna University welcomed Green Hydrogen Generation and Storage System by Ecosense.

Ecosense’s Green Hydrogen Generation and Storage System

Green Hydrogen Generation and Storage System consist of essential components:

1. Water Distiller: for water purification

2. Peristaltic Pump: to ensure optimum pressure and flow rate for electrolyzer

3. DC Power Supply powered by Solar Panels : for supplying power to electrolyzer

4. PEM Electrolyzer: for splitting distilled water into hydrogen and oxygen

5. Water separators: for separating water from generated gases

6. Hydrogen dryer: for removing moisture from generated hydrogen gas

7. Humidifier: for humidifying hydrogen and oxygen gas to be sent to fuel cell

8. Fuel Cell: for generating electricity from hydrogen and oxygen gases

9. Electronic load: for loading and testing fuel cell

10. Measurement Devices: Rotameters, Pressure Gauges etc.

11. Cylinders for storing and supplying gas

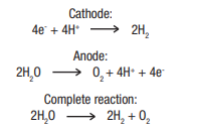

In an electrolyser cell, the electrical energy that is being provided from an external source is used to split the deionized water (or distilled water) to generate hydrogen and oxygen gases. In other words, electrical energy is being converted into chemical energy with the aid of the electrolyser cell. This electrochemical reaction is also known as electrolysis. In the electrolyser cell, the electrochemical reactions are carried out on the catalyst located at the anode and cathode. In PEM electrolyzers, anode and cathode catalysts are usually applied directly to the surface of the membrane. Sometimes, only the anode electrode catalyst is applied to the membrane surface and cathode catalyst is applied to the surface of the gas diffusion layer. An example for anode catalyst is iridium ruthenium oxide or iridium black. An example of cathode catalyst is platinum black or platinum on carbon. As the name suggest, PEM electrolyzers utilize a proton (H+) exchange membrane (such as Nafion). In addition to these components, a metallic diffusion medium is used at the anode side to evenly disperse the liquid water, vent out the generated gases, and provide electrical contact. At the cathode, on the other hand, a carbon- based gas diffusion layer is used to vent out the hydrogen gas and also provide electrical contact. The combination membrane-catalysts-diffusion media forms the heart of the PEM electrolyser cell. The following reactions take place within the PEM electrolyser system:

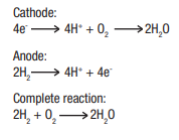

In a fuel cell, chemical energy is converted directly into electrical energy (i.e., without use of combustion process). Hydrogen and oxygen supplied from outside the process react to form water, generating electrical current and heat in the process. The oxygen can be supplied in pure form, or in the form of air. The membrane-electrode unit forms the heart of the PEM fuel cell. The following reactions take place within it:

The hydrogen gas supplied to the anode is oxidized. Under the catalytic action of the electrode (e.g., platinum), it is broken down into protons and electrons. The H+ ions migrate through the proton-conductive membrane to the cathode side. If an external electric circuit is provided to the cathode, the electrons travel to the cathode, performing electrical work in the process. The oxygen supplied to the cathode is reduced, combining with the protons to form water.

Ecosense installed Green Hydrogen Generation and Storage System at Anna University, Chennai

Technical Advantages of the System

1. Interactive Measurement Unit

2. Closed cathode fuel cell

3. Electrolyzer and Fuel Cell are rebuildable and can be dismantled and reused

4. Water cooling channel for fuel cell to get optimum performance.

Ecosense installed Green Hydrogen Generation and Storage System at Anna University, Chennai

Demonstration of Equipment Conducted

Ecosense also conducted a demonstration of equipment for training Professors and Scholars. This training program was focused on educating and training the professors, scholars, and technicians who will further train thousands of students and professionals to start their careers or business in this very field.