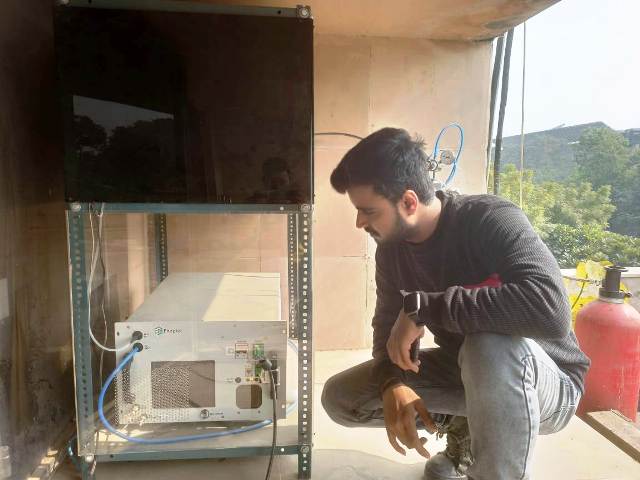

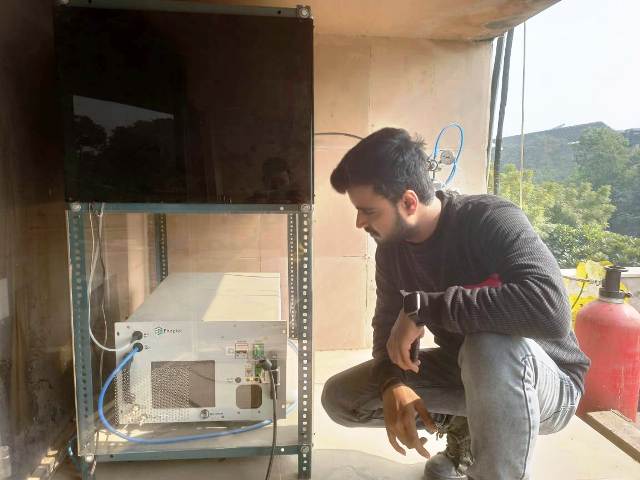

AEM based hydrogen generation system

is a technology that utilizes an AEM (Alkaline Electrolyte Membrane) to

generate hydrogen gas through an electrochemical process known as water

electrolysis. This system uses an AEM as electrolyte instead of a traditional

solid polymer electrolyte, allowing for more efficient and cost-effective

hydrogen production. The hydrogen produced can be used for various purposes,

such as energy storage, fuel for transportation and as feedstock for chemical

industry.

AEM based hydrogen generation system

work by splitting water into hydrogen and oxygen through electrolysis. During

this process, an electrical current is passed through an aqueous solution

containing a positive and negative electrode. The positive electrode, called

anode, oxidizes water to release oxygen gas. The negative electrode, called

cathode, reduces water to generate hydrogen gas. The AEM acts as the

electrolyte and serves to separate the two electrodes and transport ions

between them.

Advantages of using an AEM in hydrogen

generation over traditional solid polymer electrolytes include:

· Higher ionic

conductivity, which leads to improved efficiency and lower energy consumption.

· More tolerant to

containments and impurities, leading to improved durability and longer

lifespan.

· Higher operating

temperatures, allowing for more compact and cost-effective designs