1.

Water Purification stage

For hydrogen production,

deionized/distilled water is required as impure water can break down into

hydrogen + oxygen + harmful gases or metals, to ensure the purity of hydrogen,

distilled water is the best water. Ecosense’s Green Hydrogen Lab

comes with a small water distiller which can produce distilled water at the rate

of 1l / hour.

2.

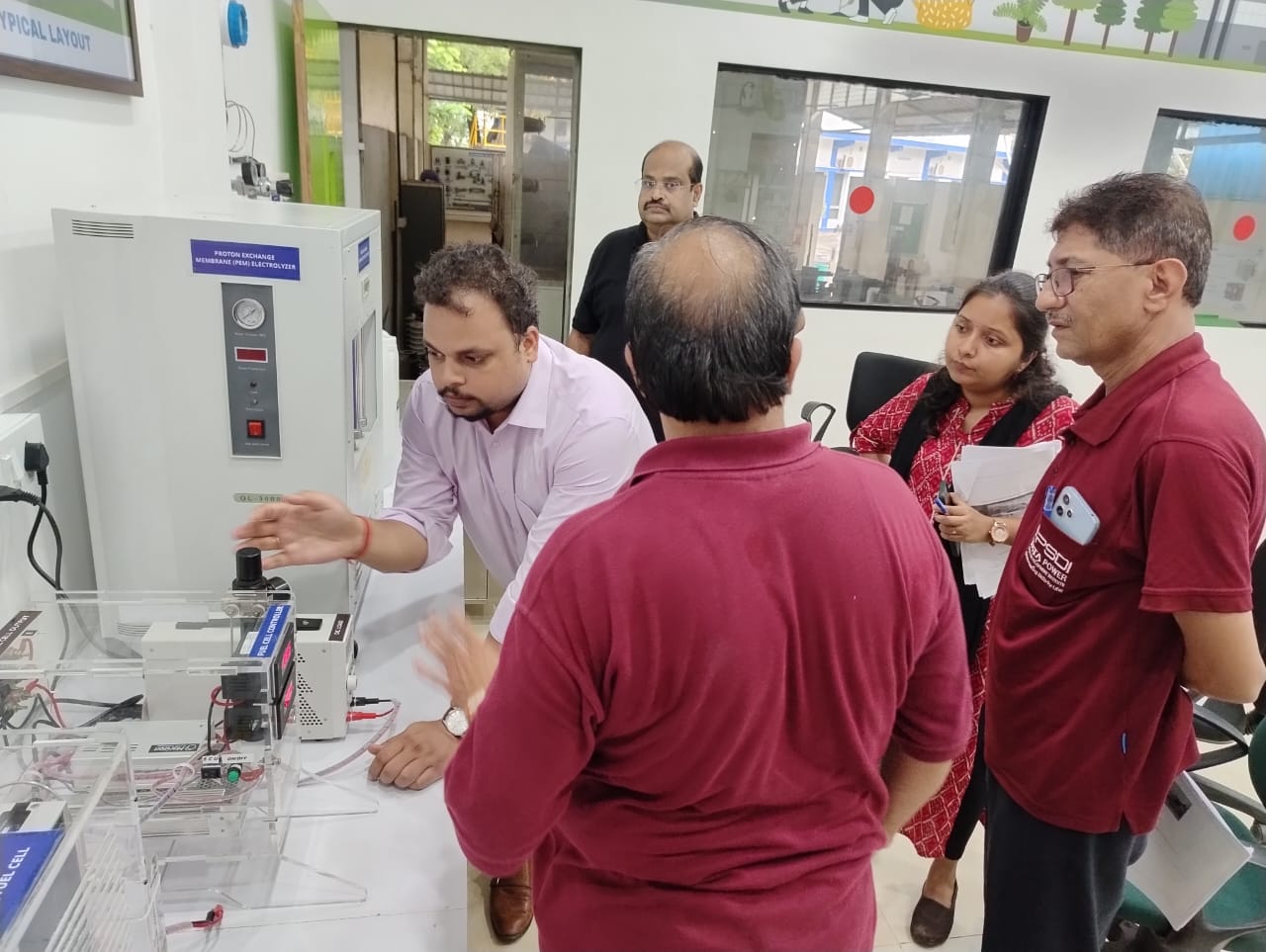

Hydrogen Production Stage

For hydrogen production two

different electrolysers are used in Green Hydrogen lab which are capable of

generating 3000 ml/min of hydrogen simultaneously as well as individually. Both

electrolysers are based on different technologies one is PEM electrolyser and

the other one is traditional Alkaline electrolyser. As this lab is an educational

lab, to teach students how different types of Electrolysers work, Ecosense

installed two different types of electrolysers instead of one. Here are the key

differences between the two electrolyser technologies:

| Parameters | Alkaline Electrolyzer | PEM Electrolyzer |

| Electrolyte | Liquid potassium hydroxide (KOH) or sodium

hydroxide (NaOH) solution | Solid proton-conducting polymer membrane |

| Operating Temperature | 60–80°C | 50–70°C |

| Current Density | Lower (0.2–0.4 A/cm²) | Higher (1–2 A/cm²) |

| Startup Time | Longer | Shorter |

| Gas Purity | Lower (requires separation processes) | Higher (directly obtained) |

| Durability | Higher (less prone to degradation) | Lower (membrane can degrade over time) |

| Efficiency | Lower (70–80%) | Higher (80–90%) |

| Cost | Lower initial cost | Higher initial cost |

| Electrode Material | Nickel-based materials | Precious metals like platinum and iridium |

| Scalability | More suited for large-scale applications | Better for smaller, decentralized systems |

Both Electrolyzers get

distilled water from the same source and starts producing hydrogen and oxygen.

The oxygen gas is released in the environment whereas hydrogen gas is collected

in a storage tank.

1.

Hydrogen Purification and Storage

Hydrogen gas coming out from

the Electrolyzers contain moisture, to separate moisture from gas a gas

moisture separator is installed along with a desiccant based dryer which soaks

up any residual moisture. The gas is then stored in a hydrogen storage tank.

2.

Electricity generation using Hydrogen

A PEM Fuel Cell is used to

generate DC Electricity using hydrogen.

A Proton Exchange Membrane

(PEM) fuel cell generates electricity by using hydrogen gas as fuel. At the

anode, hydrogen molecules are split into protons and electrons. The protons

pass through a proton-conducting membrane to the cathode, while the electrons

travel through an external circuit, creating an electric current. In a

self-humidified, open-cathode PEM fuel cell, ambient air is used directly at

the cathode, eliminating the need for a dedicated oxygen supply. The protons

and electrons combine with the oxygen from the air at the cathode, forming

water as a byproduct. This type of fuel cell is efficient, compact, and

well-suited for portable and small-scale applications.

3.

AC /DC Loading

The fuel cell is then further

connected to a charge controller, battery and inverter so that actual loads can

be connected to the system.

This is a perfect teaching

system for students who want to enter in the similar field.