The Ecosense Electric Vehicle Lab is a modular, scalable, and integrated platform designed to provide comprehensive, hands-on learning and research opportunities in the field of electrified transportation. It brings together battery technology, drivetrain systems, and charging infrastructure under one roof, enabling students, researchers, and engineers to simulate, design, test, and validate electric vehicle (EV) systems in real time.

1. Battery Technology

Battery technology is at the heart of electric vehicles, contributing to nearly 50% of their total cost. Understanding charging, discharging, battery management systems (BMS), and overall performance is critical to EV development. The lab offers two specialized subsystems for battery research:

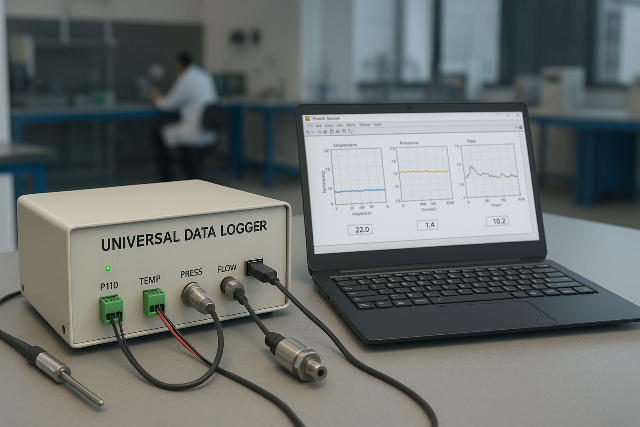

A. Battery Cycler with Data Analytics (BCDA)

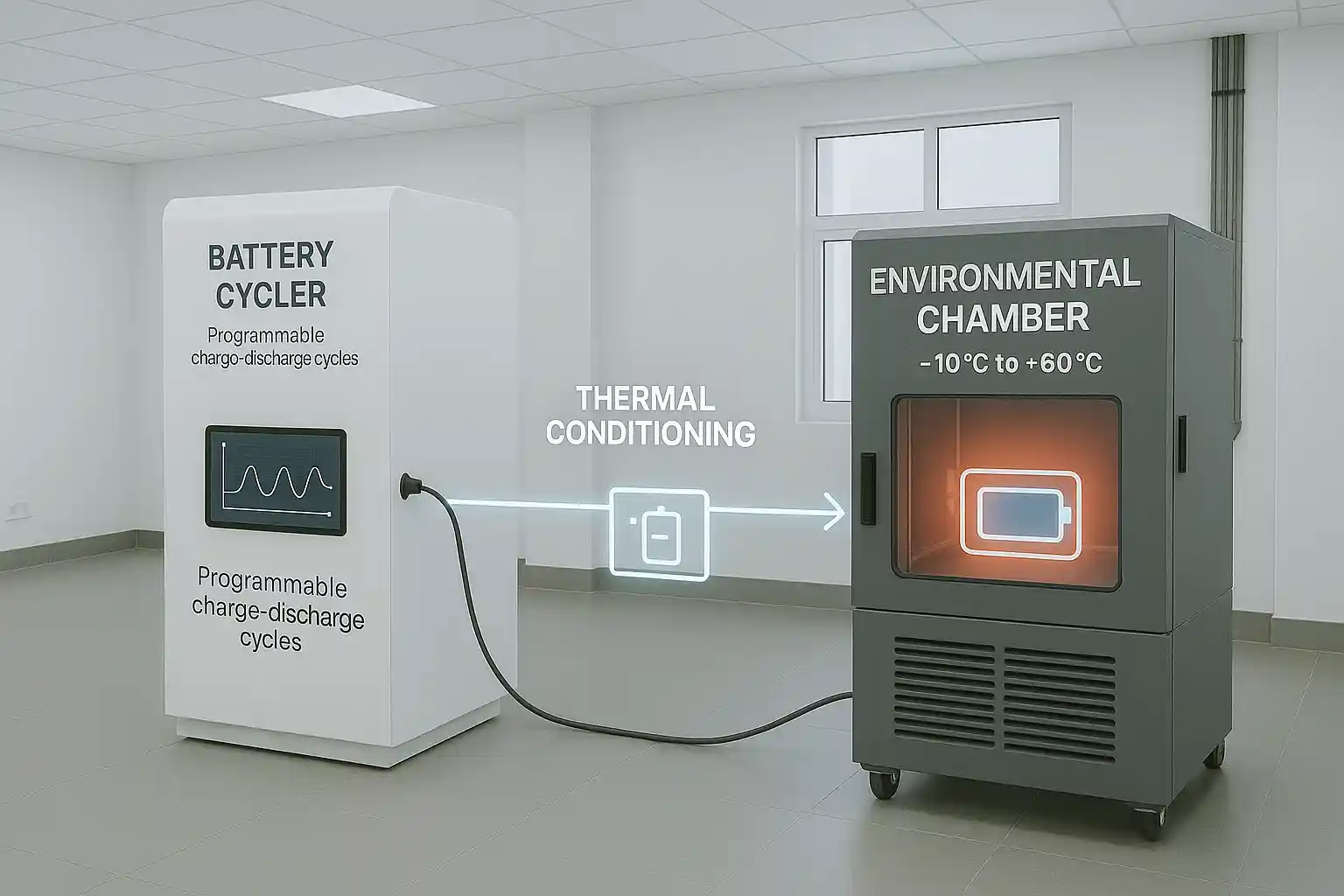

This subsystem allows controlled battery testing under varied load and environmental conditions. Users can:

- Evaluate charging characteristics using Constant Current (CC), Constant Voltage (CV), and Constant Power (CP) modes.

- Analyze discharging performance across different load cycles and C-rates.

- Study temperature-dependent behavior using the integrated Environmental Chamber.

- Perform fuel economy comparisons between new and aged batteries.

- Monitor State of Charge (SoC) and State of Health (SoH) to assess capacity and longevity.

The system workflow involves setting up test cases via application software on a PC, which communicates with a microcontroller to control the charge/discharge hardware. Real-time data on voltage, current, temperature, and SoC is logged and visualized for analysis. Users can modify algorithms because of the open-source framework, enabling experimental studies and custom research.

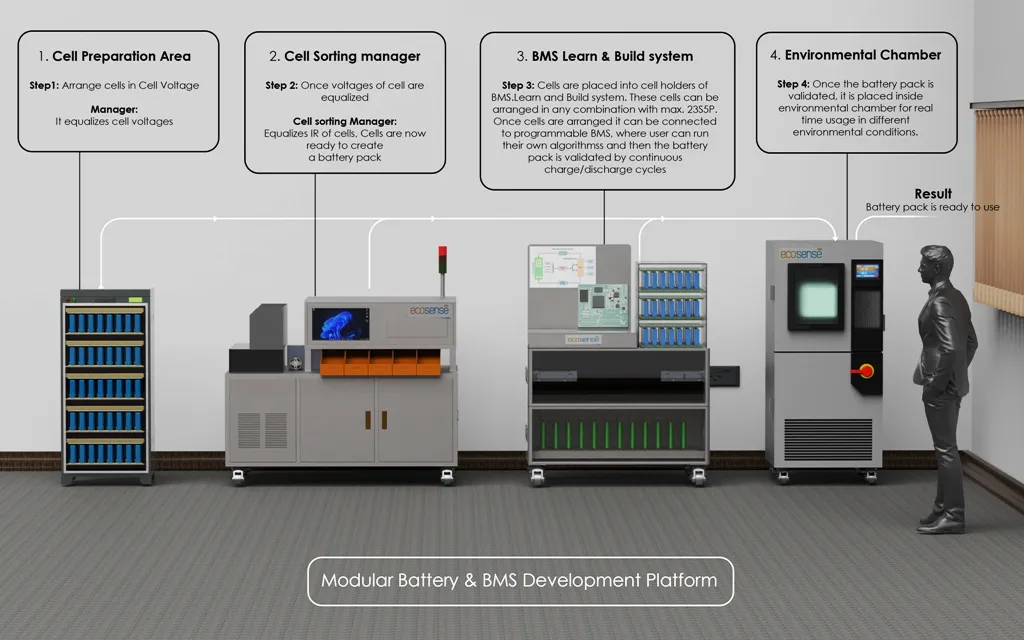

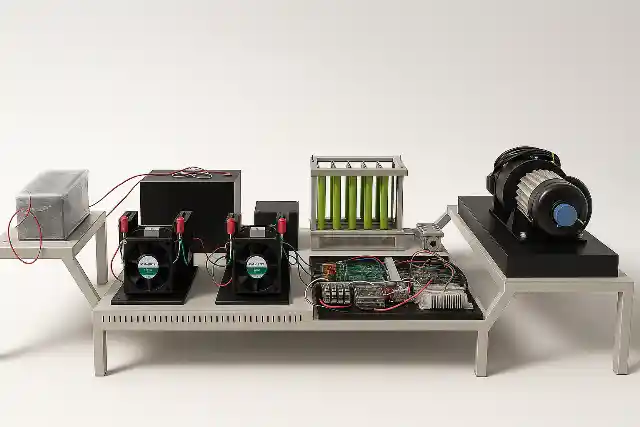

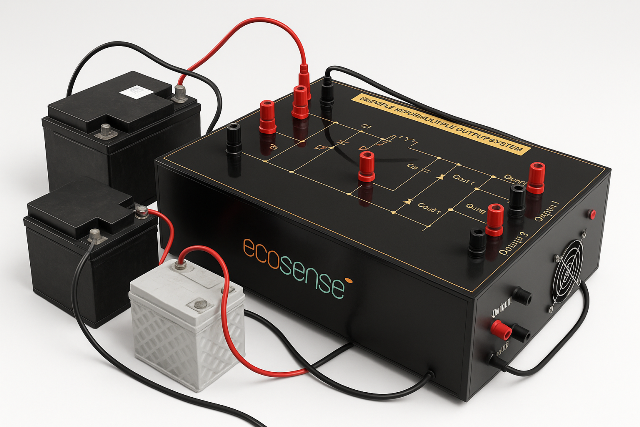

B. Modular Battery & BMS Development Platform

This platform supports battery pack assembly, custom BMS development, and algorithm validation. Key components include:

- Cell Voltage Manager: Ensures uniform cell voltages before assembly to improve performance and longevity.

- Cell Sorting Unit: Groups cells based on internal resistance to prevent imbalance and premature aging.

- BMS Development & Validation: Offers voltage, current, and temperature monitoring; protection mechanisms; active, passive, and dynamic balancing; and multiple SoC estimation algorithms such as Coulomb Counting, OCV, and Kalman Filters.

Integrated with the BCDA and Environmental Chamber, this platform allows end-to-end validation of battery packs under real-world operating conditions.

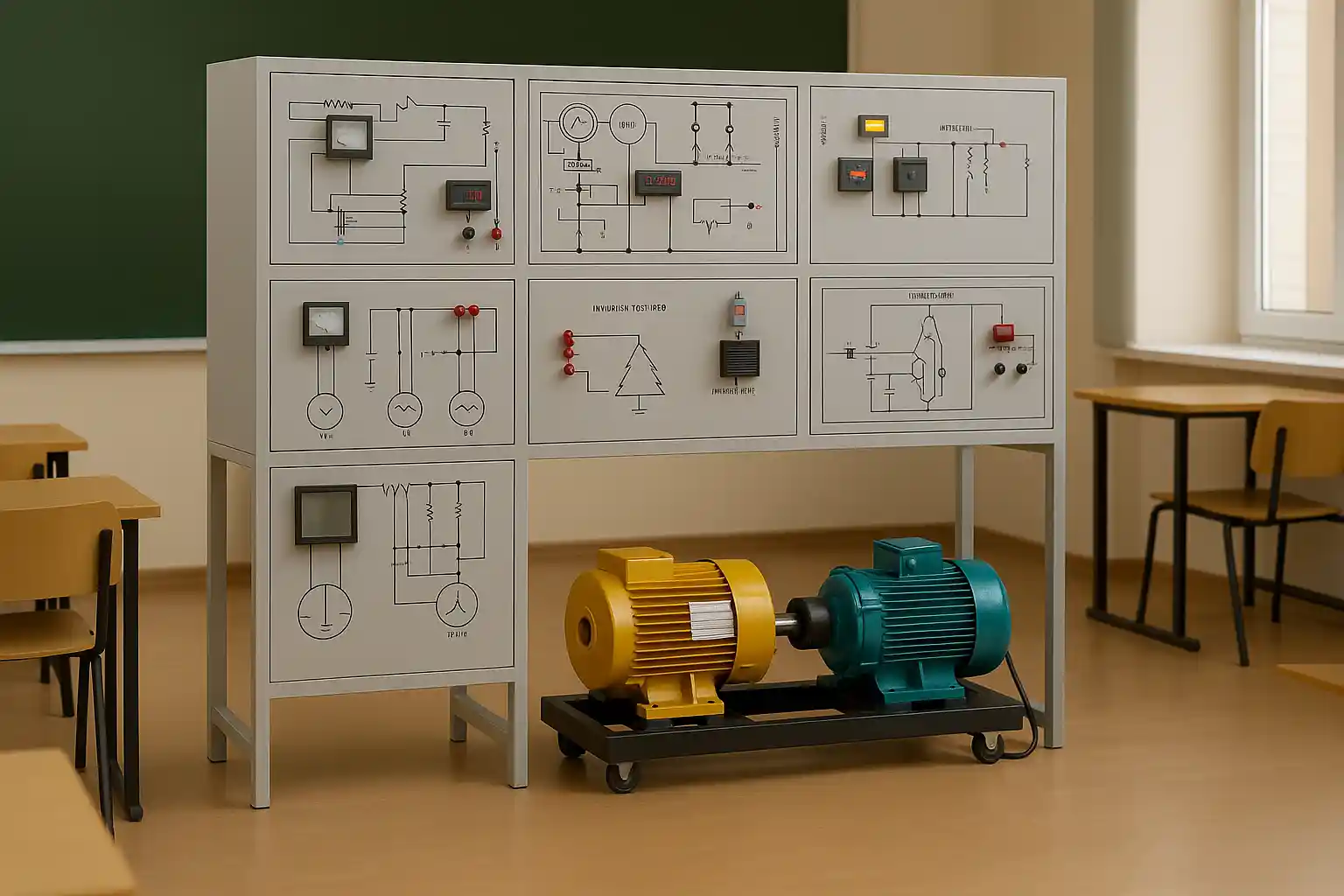

2. Drivetrain Technology

The EV Driveline Simulator with Controller Development & Validation Platform enables students to study how electrical energy is converted into mechanical energy to propel the vehicle. The subsystem includes:

The system captures real-time data on torque, speed, voltage, and thermal behavior through a high-speed data acquisition system. Users can develop custom motor control algorithms, monitor system performance, and analyze the effect of various drive cycles and regenerative strategies.

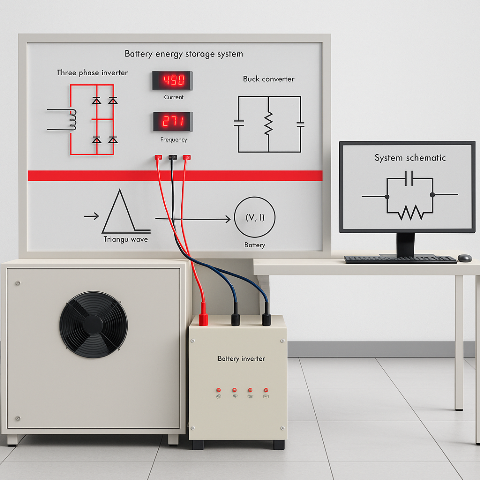

3. Charging Infrastructure Technology

The Modular & Adaptive EVSE subsystem provides a realistic training platform for EV charging technologies, supporting both onboard and offboard charging. Key features include:

-

Simulation of start-up, charging, and shutdown phases, including safety cut-offs, efficiency optimization, and fault injection scenarios.

Students can experiment with charging profiles, analyze energy flow, and optimize processes for real-world applications. Open-source software allows algorithm modification and experimentation with innovative charging strategies.

3. Charging Infrastructure Technology

The Modular & Adaptive EVSE subsystem provides a realistic training platform for EV charging technologies, supporting both onboard and offboard charging. Key features include:

-

Simulation of start-up, charging, and shutdown phases, including safety cut-offs, efficiency optimization, and fault injection scenarios.

Students can experiment with charging profiles, analyze energy flow, and optimize processes for real-world applications. Open-source software allows algorithm modification and experimentation with innovative charging strategies.

4. System Integration & Workflow

Each subsystem is designed to operate independently but integrates seamlessly into the RTSCET platform for end-to-end EV experimentation. The workflow begins with battery preparation, BMS development, and environmental testing. Once the battery pack is ready, it powers the driveline simulator, enabling motor control studies and drive cycle analysis. Charging infrastructure experiments can then be performed with the same battery system, providing a complete view of energy flow and system performance.

By combining hardware, software, and real-time simulation, the Ecosense EV Lab provides a research-ready, educational environment where users can:

In summary, the Ecosense EV Lab empowers students and researchers to simulate, design, build, and validate electrified transportation systems safely and effectively, bridging the gap between theoretical knowledge and real-world EV technology.