Battery Cycler with Data Analytics

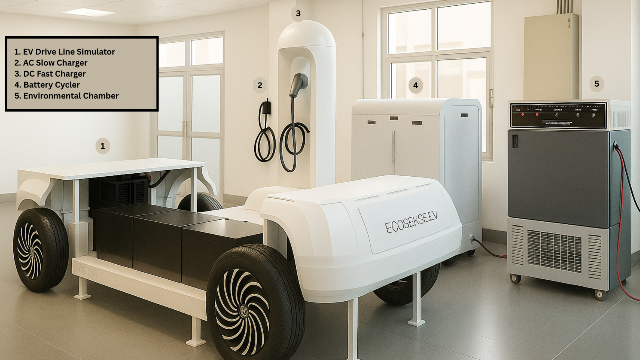

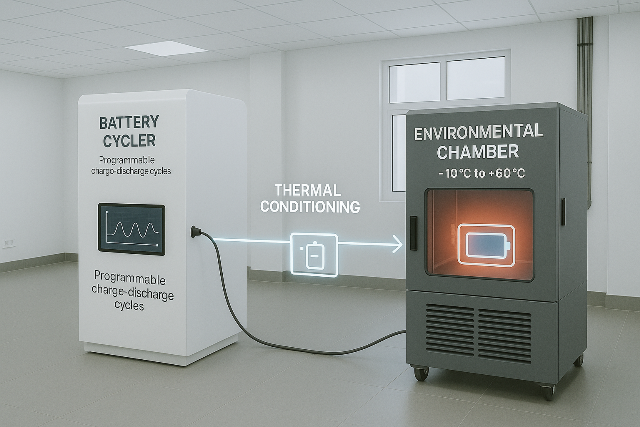

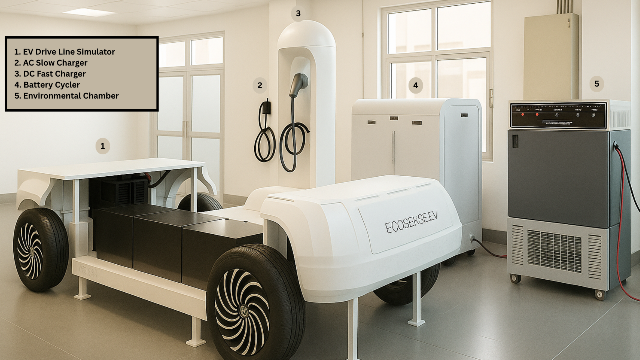

The Battery Cycler with Data Analytics (BCDA) by Ecosense is a comprehensive educational and experimental platform designed to study and analyze electric vehicle (EV) battery systems. Combining real EV components with open-source software and a built-in environmental chamber, this system provides users with the tools to conduct hands-on experiments, simulate real-world conditions, and perform in-depth data analytics. BCDA is ideal for institutions and research labs aiming to deliver practical skills and foster innovation in battery technology and electric mobility.